Continental Industrie Centrifugal Blowers Performance

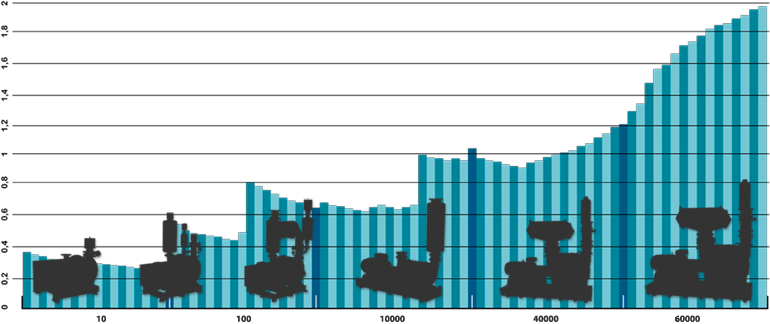

Continental Industrie centrifugal blowers and exhausters are rotating machines used to increase the pressure of a gas, ambient air or gas mixture, by means of the centrifugal force transmitted by an electric motor.

The performances are linked to the following characteristics: flow, differential pressure and power consumption. One of the main advantage is the lack of internal friction between the rotor and the body, as the shaft has only two contact points; the bearings. For this reason the expected lifetime of the machine can reach 40 years. The performances of the machine can be affected by external factors as, for instance, the deposit accumulation in the filter intake.

This problem can be avoided by following the correct maintenance instruction. Also the performance varies in accordance to the variation of the molecular weight of the gas treated, due for example to the temperature variation or the pressure at the machine intake.

The performances are linked to the following characteristics: flow, differential pressure and power consumption. One of the main advantage is the lack of internal friction between the rotor and the body, as the shaft has only two contact points; the bearings. For this reason the expected lifetime of the machine can reach 40 years. The performances of the machine can be affected by external factors as, for instance, the deposit accumulation in the filter intake.

This problem can be avoided by following the correct maintenance instruction. Also the performance varies in accordance to the variation of the molecular weight of the gas treated, due for example to the temperature variation or the pressure at the machine intake.

Casing: Cast iron or cast aluminium housings, held securely by steel tie rods. Sections are standard with internal and/or external drains.

Shaft: Polished carbon steel or stainless steel for corrosive gas applications

Impellers: Cast or fabricated high strength aluminium, available in radial or backward curved vane configurations.

Bearings: Outboard mounted, grease or oil lubrication, sized for minimum 10 years bearing life. Optional water cooled bearings are available.

Seals: Carbon/graphite rings, single for air or double for gas applications, purge capability available.

Baffle Rings: For improved airflow into the impeller eye, resulting in higher efficiency and improved performance.

Balance Piston: Used to absorb up to 75% of the axial thrust load in blowers operating at higher flows and pressure ratios.

Bearing Housing: Cast iron housing with labyrinth seals to protect lubricant from contamination.

Cooling Fans: Models 77 and larger incorporate cast aluminium cooling fans to assist heat dissipation.

Shaft: Polished carbon steel or stainless steel for corrosive gas applications

Impellers: Cast or fabricated high strength aluminium, available in radial or backward curved vane configurations.

Bearings: Outboard mounted, grease or oil lubrication, sized for minimum 10 years bearing life. Optional water cooled bearings are available.

Seals: Carbon/graphite rings, single for air or double for gas applications, purge capability available.

Baffle Rings: For improved airflow into the impeller eye, resulting in higher efficiency and improved performance.

Balance Piston: Used to absorb up to 75% of the axial thrust load in blowers operating at higher flows and pressure ratios.

Bearing Housing: Cast iron housing with labyrinth seals to protect lubricant from contamination.

Cooling Fans: Models 77 and larger incorporate cast aluminium cooling fans to assist heat dissipation.